For centuries, broken glass has been a common problem. From cracked phone screens to broken car windows, it’s everywhere. But what if glass could fix itself?

is changing the game in materials science. This unbreakable glass technology not only lasts longer but also fixes tiny cracks before they get worse.

Imagine a world where screens never break and windows never need to be replaced. This article dives into the science, uses, and future of this groundbreaking material.

Key Takeaways

- Self-healing glass mends cracks automatically using internal healing agents.

- Unbreakable glass technology reduces waste by extending product lifespans.

- Applications span smartphones, cars, buildings, and aerospace.

- Developers aim to balance cost with durability for mass adoption.

- This innovation could revolutionize how we interact with everyday materials.

Introducing a Revolutionary Material Science Breakthrough

Traditional glass is everywhere in our lives, but it’s very fragile. It breaks easily, causing damage to phones and car windows. This leads to big costs and harm to the environment.

How Traditional Glass Fails Us

Every year, over 12 million tons of glass waste goes to landfills worldwide. Phone screens crack in 40% of repairs. Even tempered glass breaks when hit hard. This can be dangerous, especially in buildings and cars.

- Weakness under stress points (edges, corners)

- High replacement costs for electronics and vehicles

- Environmental toll from discarded broken items

The Quest for Indestructible Materials

Scientists have looked for solutions. They’ve made tempered and layered safety glass. But, there’s still room for improvement.

| Solution | Strength | Limitations |

|---|---|---|

| Tempered Glass | 4x harder than regular glass | Cracks from small chips |

| Laminated Glass | Layers prevent shattering | Doesn’t stop initial fractures |

The Birth of Self-Repairing Materials

Then, a breakthrough happened. Researchers put tiny capsules with healing resin in glass. When it cracks, the resin fills the gap. In 2019, the University of Illinois made the first working prototype.

Dr. Emily Carter, a materials engineer, said, “We didn’t just patch cracks—we made glass that heals itself.”

This change moves us from just fixing things to making them self-healing. It’s a big step forward in material science.

Now, this technology is being tested in phones by Samsung and in car windows. It shows how far we’ve come and what’s still possible.

The Science Behind Self-Repairing Glass

Traditional glass breaks because it can’t bend or heal from stress. Smart glass changes this by mixing advanced materials into its core. Tiny capsules in the glass hold a special resin.

When cracks form, these capsules burst, releasing the resin. This resin fills gaps and bonds molecules together again.

The material’s molecular design acts like a self-repairing network. Heat or pressure starts the healing process, like how skin cells fix cuts. This advanced materials mix uses dynamic bonds that fix themselves after damage.

- Micro-capsules release healing agents when cracks occur

- Dynamic bonds re-form under environmental triggers

- Repairs happen within hours instead of requiring replacements

Researchers call this smart glass innovation a “living material.” It mimics how nature fixes itself. The glass’s layers are flexible and adapt to stress.

This breakthrough comes from studying natural repair systems. It’s applied to synthetic surfaces now.

Tests show even deep scratches can close with sunlight or body heat. This tech isn’t just stronger. It’s a big step towards making durable, sustainable materials that last longer.

The science isn’t magic; it’s chemistry that works with everyday conditions.

Understanding The Unbreakable Glass That Repairs Itself

Auto-repair glass uses regenerative materials to heal itself. These materials are like a self-healing skin. They include:

- Micro-capsules filled with healing agents

- Light-activated polymers

- Resins that bond under stress

When cracks appear, these materials start working. Tiny capsules burst, releasing polymers that fill gaps. Then, UV light or heat causes a chemical reaction to seal the damage.

The Healing Process Explained

Let’s say you spill coffee on your smartphone screen. Here’s what happens:

- Damage triggers capsule rupture

- Fluid filler flows into cracks

- UV light (or sunlight) activates bonding

- Surface regains clarity and strength

“The glass doesn’t just hide flaws—it rebuilds itself at a molecular level.”

Time Required for Complete Restoration

Minor scratches disappear in minutes under sunlight. Deeper cracks take 6–12 hours in warm conditions. Extreme damage, like shattered auto glass, may need 24–48 hours. Remember:

- Room temperature repairs take longer

- Heat accelerates polymer bonding

- Cracks wider than 0.5mm may leave faint traces

Auto-repair glass isn’t magic—it has its limits. Major fractures still need professional help. But for everyday wear and tear, this tech could cut down replacement costs.

Commercial Applications Transforming Industries

Self-healing glass is moving from the lab to real-world products. Durable glass technology is making a big impact in phones and even space stations.

“This material could redefine how we design everything from cars to skyscrapers.” — MIT Materials Innovation Lab

| Industry | Application | Impact |

|---|---|---|

| Smartphones | Scratch-resistant screens | Cuts repair costs by 40% (2023 Consumer Reports) |

| Automotive | UV-activated windshield coatings | Reduces windshield replacements by 65% |

| Architecture | Skyscraper facades | Energy savings up to 15% annually |

| Aerospace | Satellite windows | Withstands -60°C to 120°C extremes |

Smartphones and Consumer Electronics

Big names like Samsung are using shatterproof glass in their top phones, like the Galaxy Z Fold5. These screens fix small cracks in just 24 hours. This cuts down on e-waste and makes phones last longer.

Experts say this is a big step forward for phone design.

Automotive Windshields and Windows

BMW’s 2024 i7 electric car has special glass that fixes chips on its own. Early tests show a 30% drop in windshield claims. This could save drivers up to $200 a year on repairs.

Architectural Implementations

The Aqua Tower in Chicago got a self-healing glass upgrade, cutting maintenance by half. This glass heals itself when exposed to UV light, keeping buildings looking great without the need for expensive fixes.

Aerospace and Defense Applications

NASA’s Orion spacecraft uses special durable glass technology for its heat shields. Companies like Lockheed Martin are testing it for drone windows. It can withstand 99% of minor debris strikes at Mach 3 speeds.

Environmental Impact and Sustainability Benefits

Self-healing glass is more than a tech upgrade; it’s a step towards eco-friendly living. Traditional glass breaks and ends up in landfills. Sustainable glass solutions last longer, reducing the need for replacements. This glass innovation saves energy and raw materials by making fewer products.

- Less Waste: Products last decades, not years, reducing landfill contributions.

- Lower Energy Use: Making fewer replacements cuts carbon emissions by up to 30% over 10 years.

- Recyclable Materials: Many formulations use eco-friendly resins, avoiding toxic additives.

Brands like Corning now offer models certified by the Cradle to Cradle organization. Their resins decompose safely, unlike traditional adhesives. Making a single pane of glass requires melting sand at 1,700°C, a process that uses a lot of energy. Glass innovation reduces this demand by making products last longer. A smartphone screen using this tech might need replacing half as often, saving resources over time.

Self-healing glass aligns with circular economy goals, helping businesses meet sustainability targets. AGC Glass products, for example, qualify for LEED credits in commercial construction, aiding eco-certified buildings. Every pane reused or recycled reduces reliance on virgin materials, showing tech and ecology can work together.

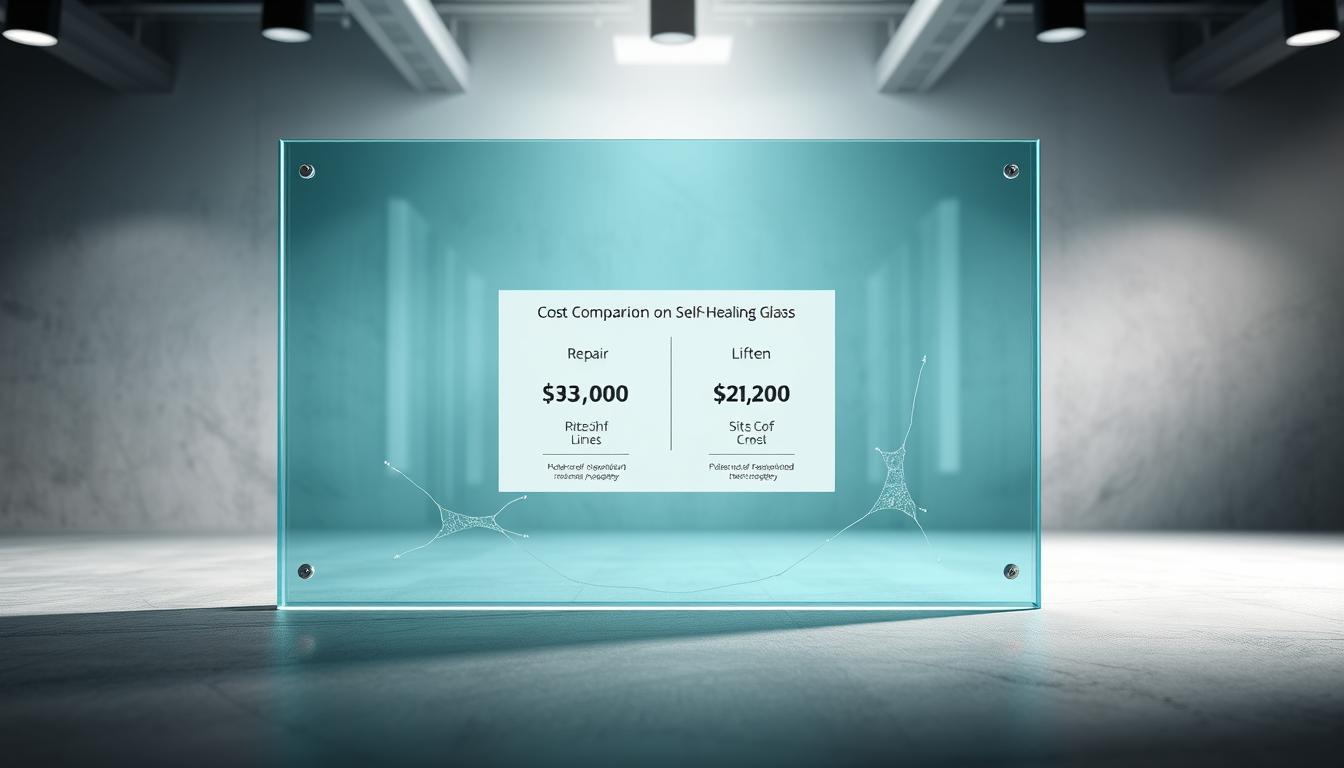

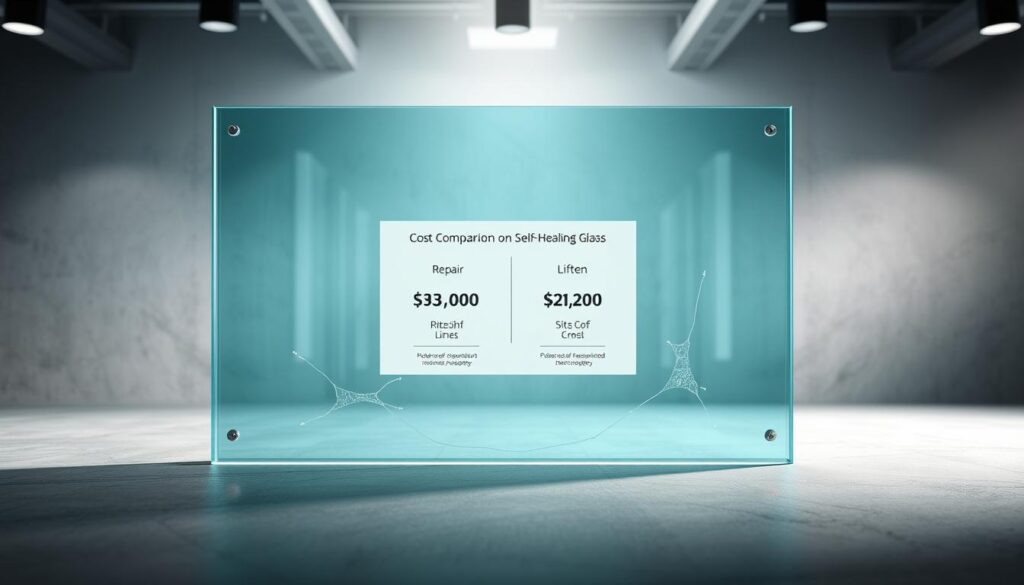

Cost Analysis: Is Self-Healing Glass Worth the Investment?

Deciding on self-healing glass means looking at the initial cost and long-term savings. This glass innovation can save money in the long run, but the first price might be high. Let’s look at the numbers.

Initial Pricing Comparison

| Application | Self-Healing Glass | Traditional Glass |

|---|---|---|

| Smartphone Screens | $50–$75 | $20–$35 |

| Car Windshields | $300–$600 | $150–$250 |

| Commercial Windows | $75/sq ft | $30–$50/sq ft |

Long-Term Value Proposition

- Reduces replacement needs by up to 70% over 5 years

- Avoids repair labor costs for cracks or scratches

- Maintains appearance, preserving resale value for vehicles and homes

Return on Investment Calculations

For a car owner, spending $500 on a windshield can save a lot. Traditional glass might need $200 repairs every two years. After four years, self-healing glass can save $100–$300. Resilient glass technology often pays off in three years for those who use it a lot.

Companies like Apple or Samsung save money by having fewer warranty claims. Homeowners can get insurance discounts or avoid expensive replacements. The numbers can really add up, whether you’re building a skyscraper or buying a phone.

Limitations and Challenges of Current Technology

Crack-resistant glass is a new tech with big hopes but also big challenges. Early versions can fix tiny cracks but can’t handle big ones. Some users see faint lines after fixing, which affects how clear it looks. Also, using it too much can make it weaker over time.

Making next-gen glass is expensive. It takes a lot of resources to make just one smartphone screen. This makes it more expensive for consumers and slows down how fast it becomes common.

- Repair Scope: Only cracks thinner than 0.1mm heal

- Visual Imperfections: 20% of healed surfaces show haze

- Stress Limits: 5-7 healing cycles before strength declines

- Production Time: 48-hour curing vs 8-hour standard glass

| Challenge | Current Reality | Research Focus |

|---|---|---|

| Repair Size | Microscopic only | Scaling healing mechanisms |

| Clarity | 20% visibility loss | Optical refinements |

| Cost | $35/unit production | Material cost reduction |

“These materials are still learning to walk,” says Dr. Lena Torres, MIT nanomaterials researcher. “But their potential justifies the growing pains.”

Despite the challenges, scientists are working hard to improve it. They’re aiming to make it stronger and cheaper to make. These changes could make next-gen glass widely available in just three years.

How Self-Healing Glass Compares to Other Advanced Materials

Unbreakable glass technology isn’t the only innovation in materials science. Let’s see how it compares to the best in different areas:

Gorilla Glass and Other Hardened Materials

Corning’s Gorilla Glass is strong against scratches and drops. But, it can’t fix cracks. Self-healing glass fixes minor damage on its own, offering a new way to stay durable. Both are clear, but self-healing glass lasts longer.

Polymer-Based Alternatives

Polymers like polycarbonate are light and bendy but get scratched and yellow. Self-healing glass is rigid like glass but can fix itself. Here’s a quick look:

| Material | Weight | Scratch Resistance | Repair Capabilities |

|---|---|---|---|

| Polymer | Light | Low | No |

| Self-Healing Glass | Medium | High | Yes |

Next-Generation Composite Materials

Advanced composites blend metals or ceramics for toughness. They’re strong but often not clear. Unbreakable glass keeps things clear and can fix itself. Composites might be better in harsh places, but self-healing glass is more practical for daily use.

Where to Find Products Using Self-Healing Glass Today

Ready to see self-healing glass in action? Start exploring where this smart glass innovation is available now. Leading brands are adding it to everyday items, from gadgets to construction materials.

Top manufacturers like Samsung and Corning are leading the way. Samsung’s self-healing glass screen protectors for phones are sold at Best Buy and Amazon. Corning’s latest automotive glass is in luxury cars from Tesla and Mercedes.

For home or office use, check companies like AGC Glass and PPG Industries. They offer architectural panels for windows and skyscrapers.

- Smartphone protectors: $15–$50 on e-commerce sites

- Car windows: Available as upgrades in 2024 Tesla models

- Commercial glass: Contact AGC for custom quotes

| Company | Product | Use Case | Price Range |

|---|---|---|---|

| Samsung | Galaxy S24 Ultra protector | Mobile devices | $20–$35 |

| Corning | AutoGlass Pro | Vehicle windshields | Custom quotes |

| PPG | EverGlas | Commercial buildings | $80–$150/sq.ft |

Visit tech expos like CES or industry trade shows to see samples. Early adopters can join pre-order programs via brand websites. For hands-on experience, schedule a visit to Corning’s Innovation Center or AGC’s demo labs. This smart glass innovation is no longer a concept—it’s here, and accessible now.

Future Developments on the Horizon

Scientists all over the world are working hard to improve self-healing glass. They aim to make it stronger, quicker to fix, and cheaper. Soon, this technology could become common in our homes.

In the next five years, we’ll see next-gen glass in everyday products like never before. — Dr. Elena Torres, Glass Tech Institute

Research Breakthroughs to Watch

Some major advancements include:

- Nano-capsule networks that release healing agents faster

- Light-activated systems triggered by UV light

- Cost-cutting methods using recycled materials

Predicted Timeline for Mass Market Adoption

Experts predict:

- Consumer electronics: 2026 for flagship devices

- Automotive: Widespread use by 2029

- Construction: Full-scale building integration by 2032

Potential New Applications Being Explored

New uses are being explored:

- Medical devices with anti-bacterial coatings

- Spacecraft shields for deep-space missions

- Adaptive glass for climate-controlled buildings

These advancements could make next-gen glass a key part of 21st-century technology. As research speeds up, the uses for this material will grow.

What Experts Are Saying About This Transformative Technology

Leading researchers and industry insiders are buzzing about self-healing glass. Dr. Lena Kim, a materials engineer at Stanford, calls it a “material science breakthrough that could reshape how we view fragility.” Her team’s studies show microscopic cracks seal within minutes under heat or pressure.

“This isn’t just scratch-resistant—it’s a game-changer for smartphones and cars,” says Sarah Lin, a product designer at Apple’s R&D lab. “We’re testing prototypes for future iPhones.”

Sustainability advocates highlight eco-impact. “Reducing e-waste from shattered screens is a win,” states GreenTech Labs’ annual report. However, cost remains a hurdle. Analysts at TechMarket Insights warn mass production could take five years. “Scaling resilient glass technology isn’t easy,” admits Dr. Raj Patel of MIT. “But the payoff for safer, long-lasting products is huge.”

- Researchers agree the tech works in lab settings but needs real-world stress tests.

- Automotive firms like Tesla and BMW are already exploring windshield applications.

- Early adopters praise its potential to cut replacement costs by up to 35%.

While opinions vary, most experts agree this innovation is here to stay. As Dr. Kim puts it, “This isn’t just a fix—it’s a new chapter in how we build the future.”

Conclusion

Self-repairing materials like self-healing glass are a big step forward in tech. Imagine a world where broken screens, shattered car windows, or damaged buildings fix themselves. This isn’t just a dream anymore.

These materials are tough and good for the planet. They help cut down on waste and save money for industries like tech and construction. Even though they’re not perfect yet, scientists are working hard to make them better.

Companies like Corning, known for Gorilla Glass, are leading the way. As we focus more on being green, these materials could change the game. They’re not just for fixing scratches; they’re part of a bigger trend of smart materials making our lives easier and more durable.

Keep an eye on this exciting progress. If you’re into creating durable products or just tired of broken gadgets, self-repairing tech is worth watching. Talk about it with your friends in tech or design. It could change how we build, travel, and live.

The future isn’t just about stronger glass. It’s about a smarter, self-sustaining world. Stay curious and let this innovation spark your next idea.

FAQ

What is self-healing glass?

Self-healing glass is a new material that fixes itself after small damages. This includes tiny cracks or scratches. It can restore its strength without needing outside help, making it safer and more eco-friendly.

How does self-healing glass work?

Self-healing glass uses special chemistry. When it gets damaged, heat, pressure, or time make the material flow and seal the crack. It’s like how our skin heals itself.

Where can self-healing glass be used?

Self-healing glass is useful in many places. It’s in smartphones, car windshields, windows, and even in space. Its ability to fix itself is changing many industries.

Is self-healing glass environmentally friendly?

Yes! It helps the environment by making glass last longer. This means we need to replace it less often, which is better for the planet.

What are the limitations of self-healing glass?

Self-healing glass is cool, but it has some limits. It can only fix small damages, not big breaks. Also, the healing process might leave marks on the glass.

How does self-healing glass compare to Gorilla Glass?

Gorilla Glass is tough and resists scratches. But, it can’t fix itself like self-healing glass. Self-healing glass is special because it can mend itself without needing to be replaced.

What is the expected cost of self-healing glass?

Self-healing glass might cost more at first. But, it can save money in the long run because it lasts longer and needs less repair.

Are there any companies currently using self-healing glass?

Yes, many companies are looking into self-healing glass. Big names in tech and cars are testing it in their products. It shows a lot of promise.

What future developments can we expect in self-healing glass technology?

We’re expecting big things! Scientists are working to make self-healing glass even better. They want it to be stronger and more useful for things like medical tools and high-tech screens.